What make GBC replacement inner fender different to others

Material selection on production

The plastic material used on GBC production is subject to OE(CCS) and they are tested by the CAPA approved labs to verify the physical properties within tolerance as below.

- Material thickness(mounting point and center)>0.05mm

- Tensile strength > -10%

- Impact test > -10%

- Coefficient of liner thermo expansion < +20%

- Heat aged tensile >-10%

- Heat deflection>-10%

- Non woven fabric (sound barrier) test require TGA, DSC, thickness, mass and density, Length and width

- GBC material source from “Formosa Chemicals & Fibre Corporation”

.

.

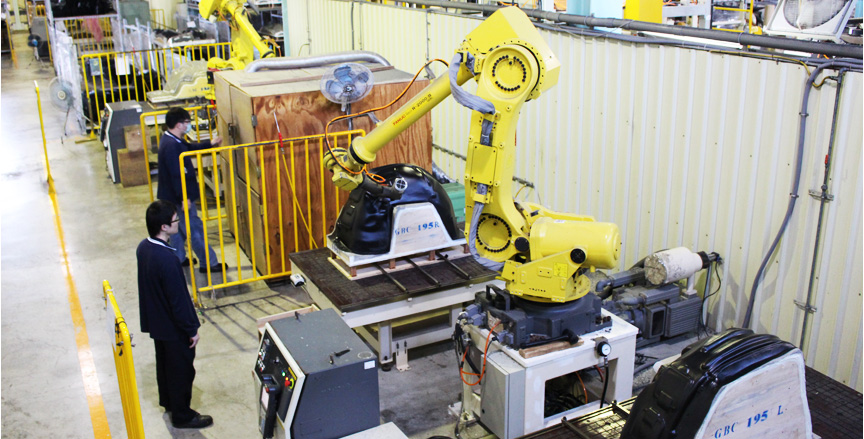

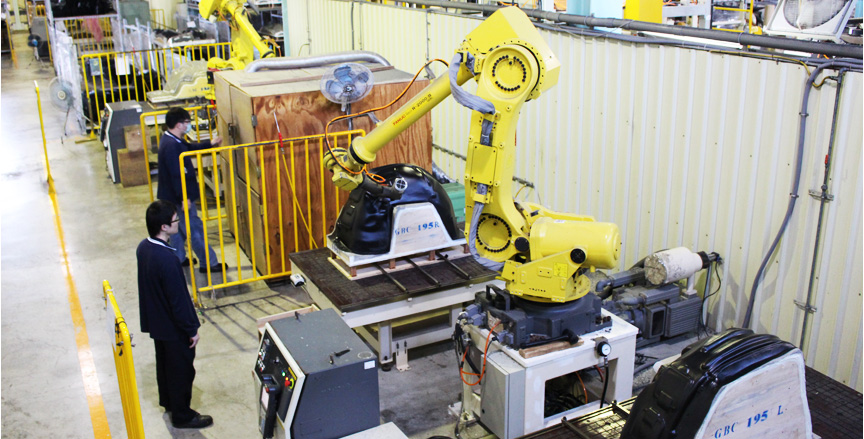

In house manufacturing

- Over 11 years of production experience on the inner fender, GBC now owns.

- 2 factories, total over 220,000 square feet production base.

- Warehouses space, 200,000 square feet with more than 180,000 pcs stock available.

The production features

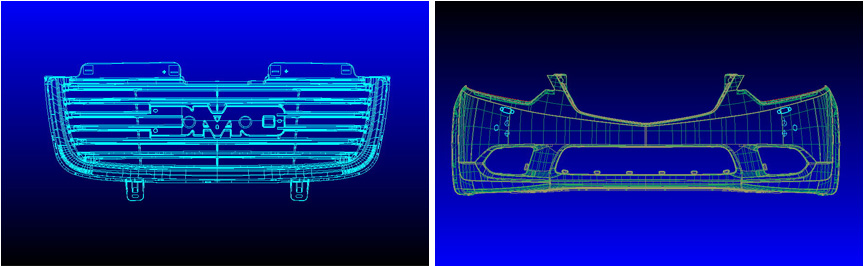

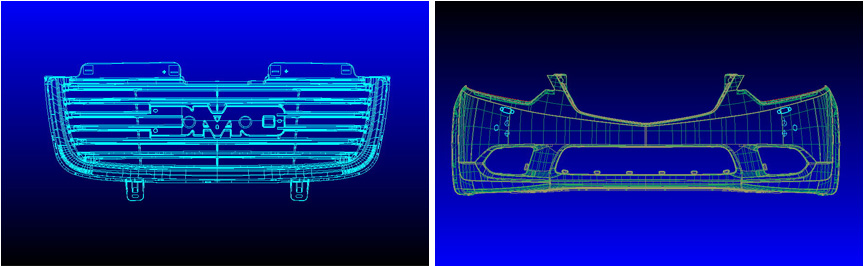

- Engineering over Injection, vacuum and composite material.

- Injection tooling design.

- Robotic CNC drilling for precise mounting hole.

- Plastic injection forming.

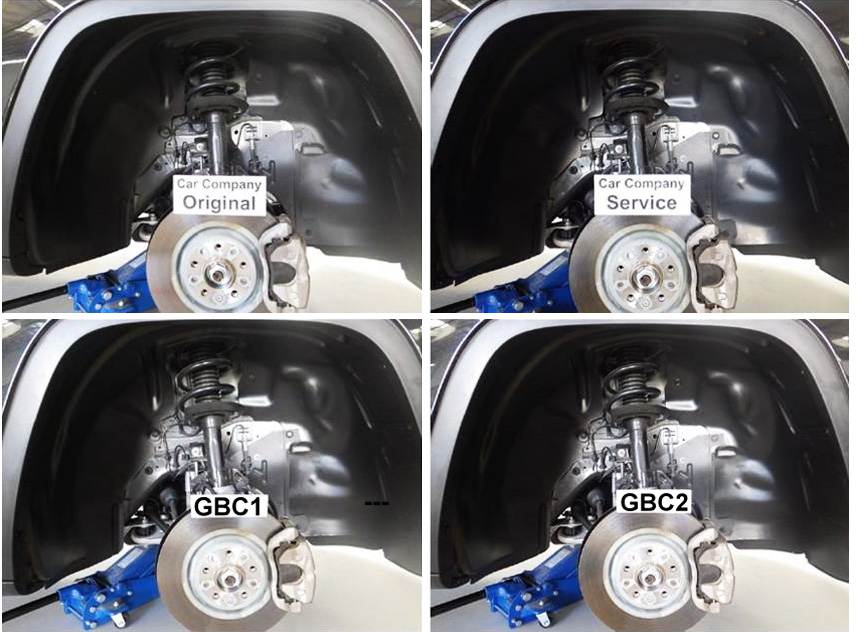

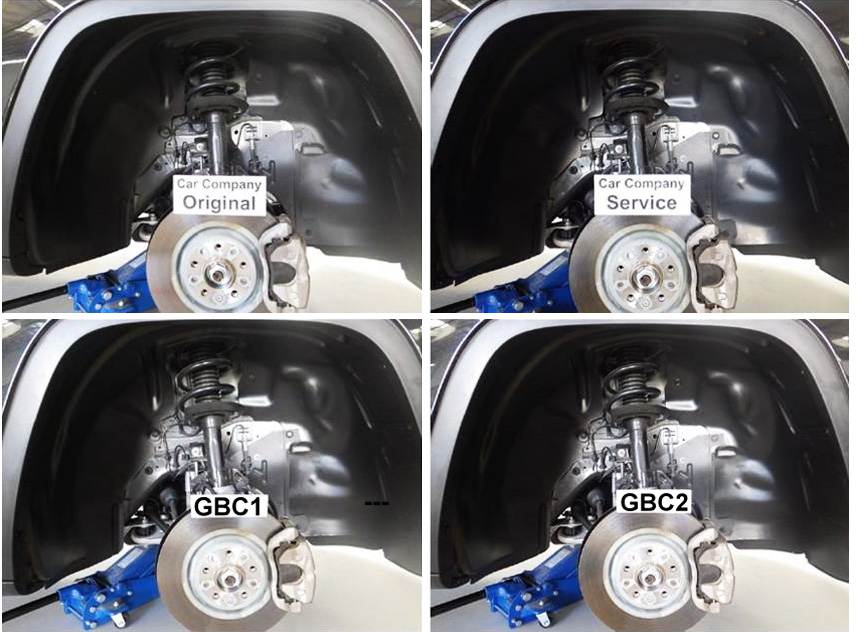

Fitting Guaranty

Verified by certification organization, GBC certified inner fender must pass the actual vehicle test fit from the US workshop before mass production.

Why choose GBC replacement inner fender

- In house manufacturing, better QC from the material to final assembly on every production.

- Similar material, appearance, components and function to the OE.

- Better finishing and more durable than the other A/M brands.

- Item individually certified by “CAPA”.

- The application covers most US fast movers, the largest certified inner fender manufacturer.

- Good fitting, precise mounting holes’ position, easy installation, saving repair time half hour up to an hour.

- Insurance companies adopt GBC inner fenders on the collision vehicle repair.